Work was carried out between 22.00hrs and 06.00 hrs daily over consecutive night shifts.

Our rigging and removal plan was signed off by structural engineers.

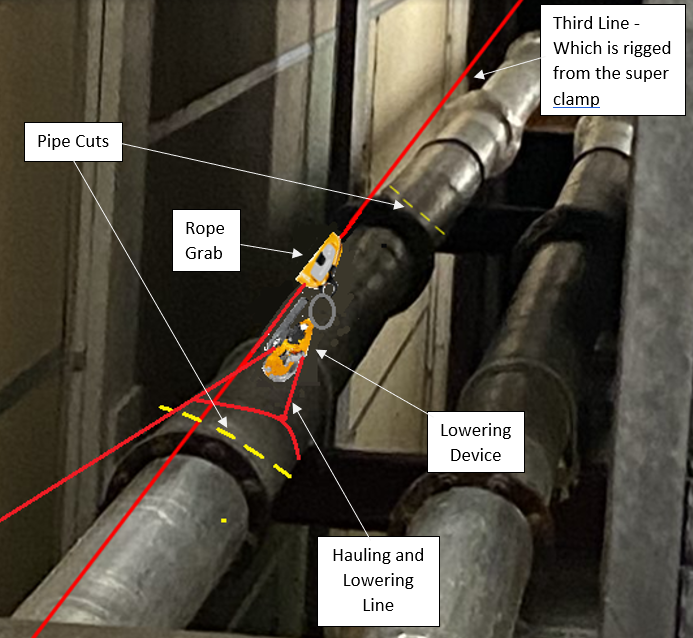

Rope Access techniques were used to enable technicians to carry out the sectional cutting of the pipework in individual lengths enabling safe removal of the pipework from the site.

Chain and rope pulley systems were attached to existing structural beams at strategic levels of the riser void allowing the team to use a choke retaining method for stability and securely lock in the pipework into the rope system whilst the pipework was cut across at 1.5m centres.

Each pipe section having been cut free and supported by the rope pulley system, were then lowered in a controlled manner to slab level platforms below and then transferred to each lower level thereafter. At the 3rd floor level, each cut section of riser pipe was then collected and layered safely for handing over to M&E contractors for safe manual handling for disposal by others.